EXPLORE CASA FASHIONS

With million dreams, created in 2016, CASA FASHIONS is the result of aspirations of two young textile minds. CASA FASHIONS is a first generation business and enterprise from the orthodox family of farmers. Every yarn and dye we use in our products are selected after intense scrutiny and tailored best to meet out the quality. Every part of our curriculum was examined and experimented in the mills , looms, and in all the process. After years of study and intern, we have arrived at the best process for every product we do.

DESIGNING

Our design team is a group of highly skilled professionals who bring creativity, innovation, and excellence to our products. Their work plays a crucial role in shaping our environment, products, and services.

PROCESSING

- Yarn Dyeing – Integrated Dyeing Unit includes both cabinet and cheese dyeing with production capacity of 3 tons per day

- Fabric Dyeing – Efficient and effective jigger and soft flow dyeing facility with production capacity of 10,000 meter per day

- Printing – Versatile Printing facility in all the different techniques – Screen Printing, Rotary Printing, Digital Printing

- Special Finishes – Have good collaboration with a processing unit for special finishes like water resistant, fire retardant, stain resistant, anti bacterial and so on..

Yarn Dyeing

Fabric Dyeing

Printing

WEAVING

The magic of desired fabric is woven in our looms. We manufacture over 5000 meter per day with dedicated team of suppliers with around 50 autolooms, 10 jacquard looms and 5 warping machines.

CUT TO PACK

- Stitching – In house 150 Singer machines and 5 overlock machines and ability to collaborate upto 500 machines with a capacity of making 5000pcs per day

- Checking – Skilled labours screening the products at each and every stage

- Packing – Proficient labours to pack simple to complicated packing

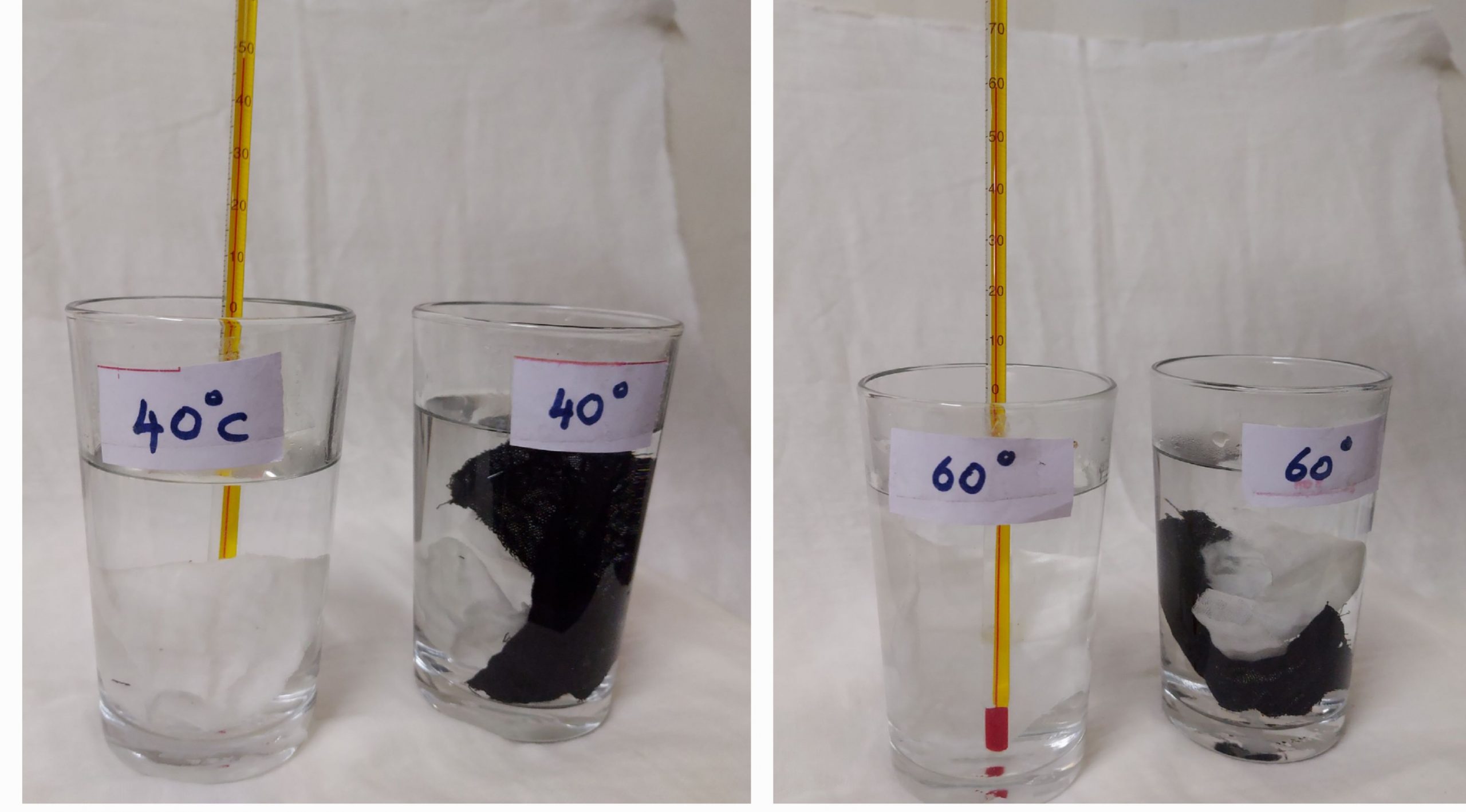

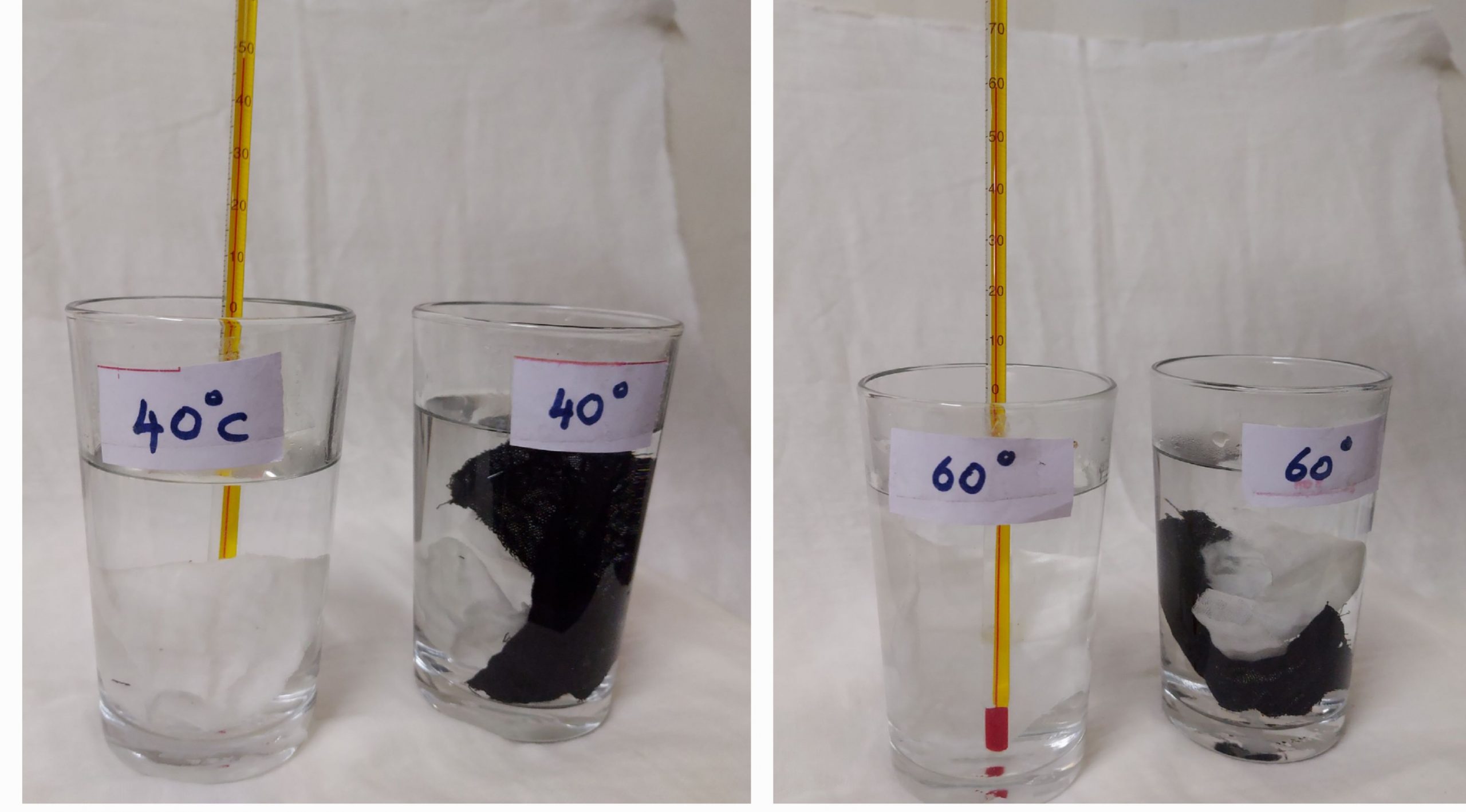

TESTING

Quality is our first priority. We do testing in two stages. One internal testing before going for bulk and the other third party testing reports to clients from SGS and Intertek.

DESIGNING

Our design team is a group of highly skilled professionals who bring creativity, innovation, and excellence to our products. Their work plays a crucial role in shaping our environment, products, and services.

PROCESSING

- Yarn Dyeing – Integrated Dyeing Unit includes both cabinet and cheese dyeing with production capacity of 3 tons per day

- Fabric Dyeing – Efficient and effective jigger and soft flow dyeing facility with production capacity of 10,000 meter per day

- Printing – Versatile Printing facility in all the different techniques – Screen Printing, Rotary Printing, Digital Printing

- Special Finishes – Have good collaboration with a processing unit for special finishes like water resistant, fire retardant, stain resistant, anti bacterial and so on..

Yarn Dyeing

Fabric Dyeing

Printing

WEAVING

The magic of desired fabric is woven in our looms. We manufacture over 5000 meter per day with dedicated team of suppliers with around 50 autolooms, 10 jacquard looms and 5 warping machines.

CUT TO PACK

- Stitching – In house 150 Singer machines and 5 overlock machines and ability to collaborate upto 500 machines with a capacity of making 5000pcs per day

- Checking – Skilled labours screening the products at each and every stage

- Packing – Proficient labours to pack simple to complicated packing

TESTING

Quality is our first priority. We do testing in two stages. One internal testing before going for bulk and the other third party testing reports to clients from SGS and Intertek.